Vision: Production Management Software

Micro Spring & Presswork Ltd

Manufacturing, Metalworks

Multi Platform Factory Workflow & Production Planning system

- .NET Core 2.2

- Angular 8.0

- Web API

- Third Party API Integration

Background and challenge

Running a multi-team, large-scale manufacturing process

MSP is a major manufacturer of stampings and springs. From its Redditch base, the company serves customers throughout the globe. Producing these components in a range of materials, for diverse environments, for various industries creates a huge challenge for workflow organization – which was previously managed through a series of spreadsheets.

The company required a more efficient way of working, including a better process to manage by exception and quickly highlight and mitigate potential bottlenecks

The Solution

Keeping on top of a busy workflow

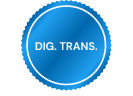

When ioSTUDIOS was presented with MSP’s challenges, our developers set out to create Vision – one system that uses multiple devices, placed strategically across the factory floor to aid planning and production. ioSTUDIOS tried and tested development process was followed for this to ensure no stone was left unturned, and the client would be left with a system that could suit their needs.

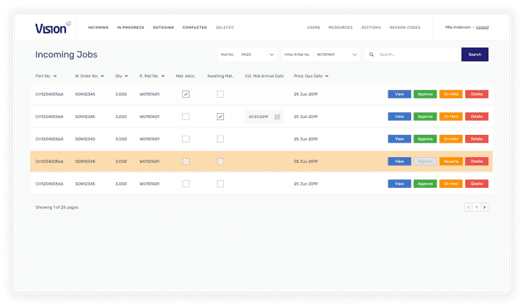

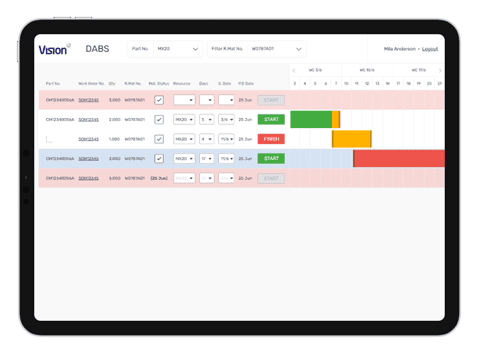

Vision brings in all orders automatically from the company’s CRM system and places these into a table for Team Leaders and the Production Supervisor to plan accordingly. Once this information is planned it is displayed on a Gantt chart with colour-coordinated project status information. Team Leader can then manage production to ensure deadlines will be made - if it becomes apparent a deadline is going to be missed, they can replan and update their planner GANNT chart accordingly - such changes will show in real-time to the rest of the factory.

Vision is particularly useful for Production Supervisors who will have a God’s-eye view of all sections and schedules, as well as the ability to approve new projects, specify materials for each job, and create and manage various system settings.

To improve transparency and visibility across the factory, each teams real-time GANNT chart planner, with real-time statuses of whether each job is ahead/behind schedule is also displayed on a large, widescreen television at that Team's specific area in the factory.

The Outcome

More efficient workflow management

As Vision enables management to keep on top of the vast detail they have across the factory floor, potential production “bottlenecks” are now addressed before they become a problem. In turn, this saves 100's of manufacturing hours a year and has led to a 15% decrease in the lead-time given for new projects.

MSP is also able to leverage valuable insights from the system’s large dataset – such as which team is the most efficient or how long a specific type of job takes to complete.

MSP’s management has full control over the software. Its configurability means different areas and settings in the system can be adjusted from a simple menu and as Vision has been built in a manner that allows modules to be easily added on, future development phases and functionality are easy to achieve.